BCG Wear parts

our products

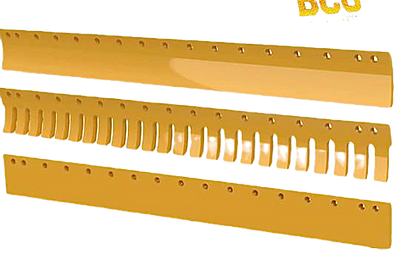

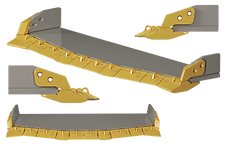

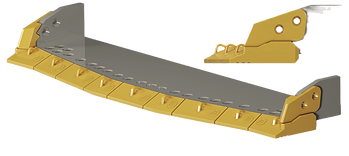

Grader Cutting Edges

Blades available in double bevel curved, double bevel flat, serrated or non- serrated. Curved blades from 6" and 8" wide. Speciality blades from 10", 13", and 16" wide. The curved shape of the blades results in better material flow when used on graders and underbody plows. Tungsten carbide inserts result in a blade with extremely long wear life, allowing for fewer blade changes and an excellent resistance to crowning for applications that require a level grading operation

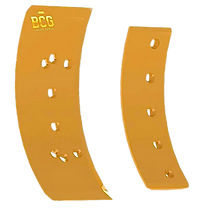

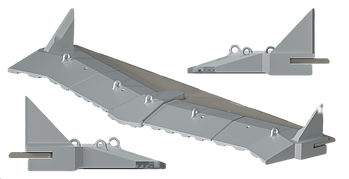

Bulldozer Cutting Edges & End Bits

Bulldozer cutting edges and end bits are precision-engineered for maximum durability and performance. Available in straight, curved, and serrated designs, these cutting edges are crafted from heat-treated steel or reinforced cast materials to withstand extreme wear and tear. End bits provide additional strength and protection for blade corners, ensuring extended service life. Designed for a wide range of applications, these cutting edges and end bits offer superior penetration and efficient material flow. Tungsten carbide-reinforced options deliver exceptional wear resistance, minimizing downtime and replacement costs. Compatible with various bulldozer models, they are ideal for challenging tasks like grading, leveling, and heavy earthmoving operations.

Ripper Teeth, Shanks, Protectors

We offer a wide range of wear parts, including ripper teeth, scarifier tips, scarifier shanks, shank protectors, replacement nose, and quarter shanks, all of which add value to our customers' operations. Trust Black Cat for quality, durability, and reliable performance every time.

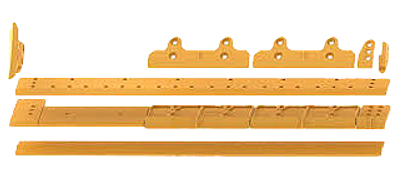

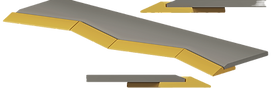

Loader Cutting Edges

Bolt on loader edges and segments have the most options available and are some of our most often customized products. Because there is very little interference on the bottom of a bucket, there is an almost endless possibility for customizations.

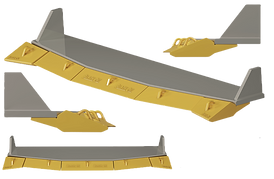

LHD Lip Shrouds

Straight bucket systems offer great flexibility and are designed to accept either bolt on edges or teeth and segments. Base edges are drilled so that machines can quickly be converted from one system to the other without any welding

Excavator & Loader Buckets

Excavator and loader buckets are designed to handle a variety of materials and applications, including digging, loading, grading, and trenching. Built with high-strength steel and wear-resistant reinforcements, these buckets deliver excellent durability and performance in demanding environments. Available in standard, heavy-duty, and specialty designs, the buckets are tailored for tasks ranging from light material handling to heavy excavation. Cutting edges and side cutters are heat-treated for enhanced wear resistance, ensuring long service life. Optional features include quick-attach systems for seamless equipment changes, reinforced corners for added strength, and customizable sizes to match specific operational requirements. Perfect for construction, mining, and agricultural applications, these buckets maximize efficiency and productivity.

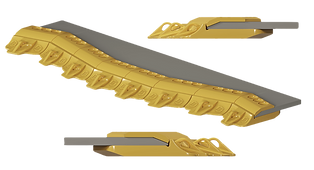

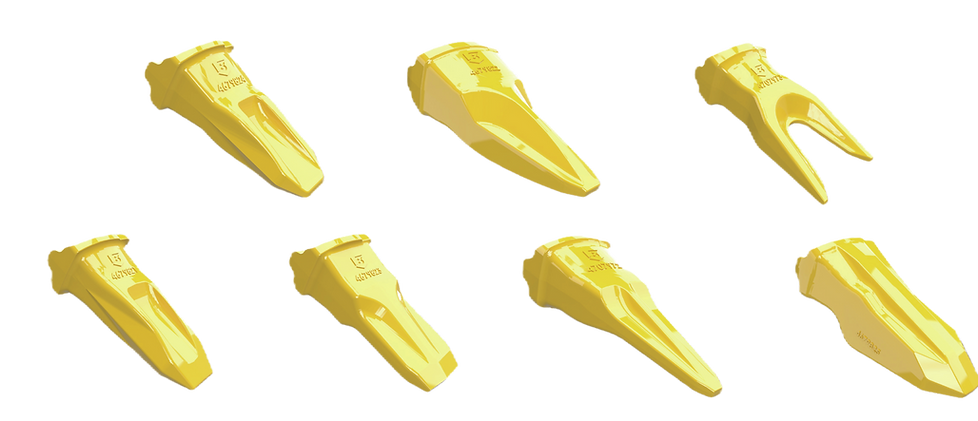

DRP J - Teeth

Replacement Teeth and Adapters are manufactured using our HighSpec Alloy steel and heat treated to our precise specifications. Computer design and analysis is employed in the development stages to ensure proper fitment and optimum strength for every part. Efficient processes and “state of the art” foundry practices allow for competitive pricing of quality parts. In house metallurgical staff and testing facilities ensure quality and consistency in all of our finished products. The results are quality wear parts that offer value to the customer every time

DRP K - Teeth

DRP K-style teeth are designed for excavators and loaders, offering superior performance in heavy-duty digging and loading applications. Crafted from high-quality alloy steel, these teeth are engineered to provide exceptional wear resistance and durability in abrasive environments. Available in multiple configurations, including standard, heavy-duty, and twin-point options, these teeth ensure optimal penetration and material retention for various tasks. Their streamlined design reduces drag, increasing efficiency and fuel savings. Quick and secure attachment systems allow for easy installation and replacement, minimizing downtime. Perfect for construction, mining, and quarrying operations, DRP K-style teeth enhance productivity and extend the life of your equipment

DRP Super V - Teeth

We offer a wide range of wear parts, including ripper teeth, scarifier tips, scarifier shanks, shank protectors, replacement nose, and quarter shanks, all of which add value to our customers' operations. Trust Black Cat for quality, durability, and reliable performance every time.

DRP SV2 - Teeth

Trenching Bits

DRP SV2 teeth are designed to replace and enhance ESCO® SV2 systems, offering exceptional performance in tough digging and loading applications. Manufactured from high-strength alloy steel, these teeth provide superior durability, wear resistance, and impact strength, ensuring a longer lifespan even in the most demanding conditions. Available in various profiles such as standard, rock chisel, tiger, and twin tiger, the DRP SV2 teeth are tailored for optimal penetration, material flow, and reduced drag. Their secure locking system ensures a tight fit and easy installation, minimizing downtime during replacements. Ideal for excavators, loaders, and other heavy equipment, these teeth deliver maximum productivity and reliability in mining, construction, and earthmoving operations

Trenching bits are engineered for precision and durability in trenching and excavation applications. Designed to handle various soil conditions, including hard rock and compacted earth, these bits are constructed from high-grade alloy steel and feature tungsten carbide tips for enhanced wear resistance and cutting efficiency. Available in conical, flat, and pick-style designs, trenching bits ensure optimal performance for trenchers, rock saws, and other specialized equipment. Their rugged construction minimizes downtime and replacement frequency, providing consistent productivity in demanding environments. Ideal for utility installations, construction, and mining, trenching bits deliver reliable performance and extended service life for all trenching needs

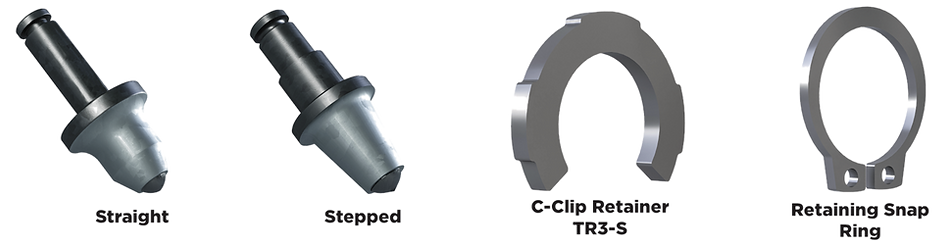

Cutting Edge Hardware

Cutting edge hardware includes bolts, nuts, and washers designed for secure and reliable attachment of cutting edges to heavy machinery. Manufactured from high-strength, heat-treated alloy steel, this hardware is engineered to withstand the intense stresses and vibrations of demanding applications, ensuring a long-lasting and secure fit. Available in a variety of sizes and thread configurations, the hardware is compatible with a wide range of cutting edges and machinery, including bulldozers, graders, and loaders. Corrosion-resistant coatings provide additional durability, even in harsh environments. Cutting edge hardware is essential for maintaining operational efficiency and ensuring the safety and performance of your equipment during heavy-duty operations